3D Printing Boyscout To The Rescue As He Invents Accessory to Make Masks More Comfortable

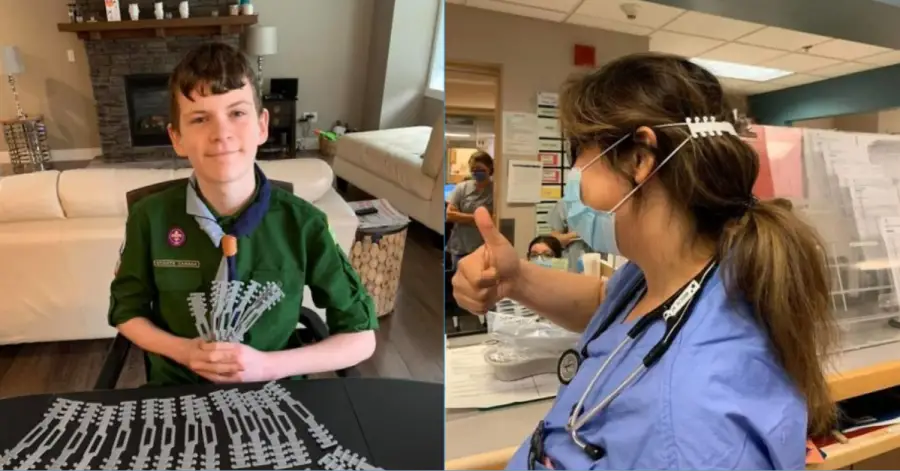

A boyscout from Canada answered the call of his local hospital by using his 3D printing skills to design an ear guard which will make face masks more comfortable for medical workers to wear.

Personal protective equipment including facial masks is vital for medical and other essential workers during the coronavirus pandemic.

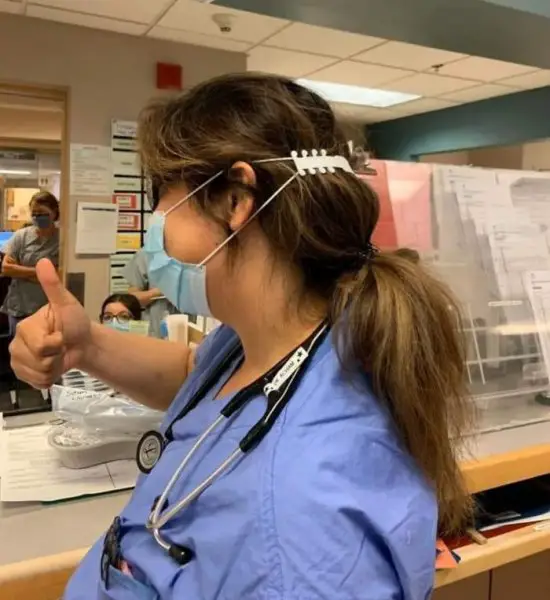

But hospital workers in particular are finding that wearing the masks all day long becomes painful due to the strap being attached around their ears.

Read more: Incredible 3D-Printer Hack Can Convert Snorkelling Masks Into Ventilator

So when one Canadian hospital asked for help to remedy for the problem, up stepped boyscout Quinn Callander.

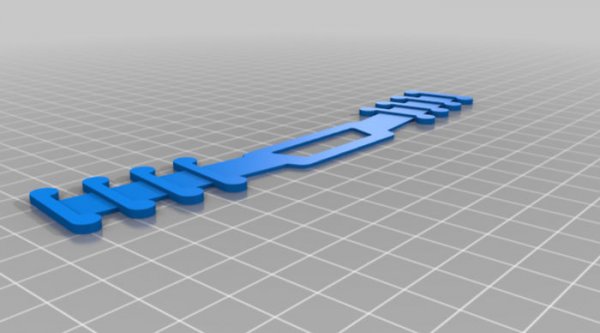

He came up with a simple plastic strap which is placed at the back of the head, allowing the pressure to be taken off the ears. There are a number of different hooks on the device which enables adjustment to the tightness.

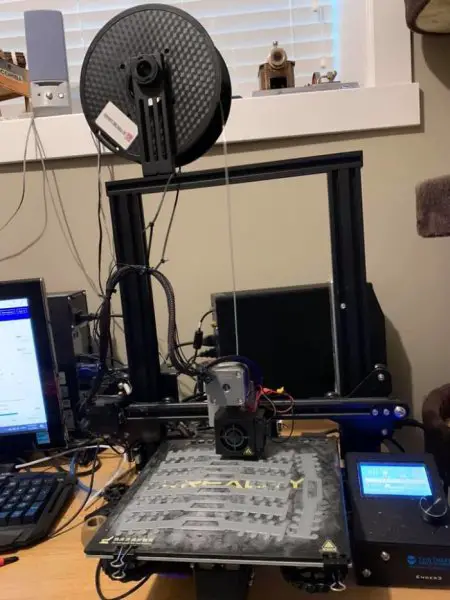

According to his mom, Heather, Quinn has been producing dozens of these mask accessories every day. He’s also made the computer file available for anyone to download.

The hope is that more people will start producing the ear guards.

“We need more volunteers to fire up their 3D printers and donate these ear guards to hospitals and medical professionals!” said Heather.

3D printing proving useful in the fight against coronavirus

Global 3D printing service company Materialise has made available files for a hands-free door handle attachment which would help prevent the spread of coronavirus and make hospital workers’ lives a little easier.

An Italian 3D printing company called Isinnova teamed up with a French diving mask business called Decathlon in order to turn snorkelling masks into ventilators.

In a variety of industries, manufacturers are facing a shortage of parts due to coronavirus -related supply-chain breakdowns. 3D printer company Beamler has offered their services to help solve this problem.

“Beamler has an extensive network of 3D printers. With over 1200 materials and 25000 machines in as much as 40 countries. We oftentimes are able to supply within 2-3 days,” their website stated.

Pic credits: Hebby

Leave Comment: