Scientist Have Discovered How To Convert Human Waste Into Bricks

Tags: News

In the search for more sustainable building materials, scientists have discovered a way to transform human waste into bricks that can be used for building.

However, human feces only accounts for 25% of the material in the bricks, the remaining 75% is made out of traditional clay. Even with using mostly clay, this process would still cut down on 30% of the biosolid material that is sent away to landfills, according to a recent study conducted by researchers from RMIT University in Australia

The study, published in the journal Buildings, explained that:

“Millions of tonnes of leftover biosolids are increasingly stockpiled every year around the globe. Biosolids are a product of the wastewater sludge treatment process. Stockpiles necessitate the use of large areas of increasingly valuable land. Biosolids have many beneficial uses and are currently utilised in agricultural and land rehabilitation applications. However, it is estimated that 30% of biosolids are unused and stockpiled.”

In the study, prototypes of these bricks were made and tested to compare with traditional building materials. The tests found that the bricks were sturdy and would hold up to the most stringent global building regulations. The creation of the bricks also uses less energy than traditional building materials, and they are better for insulation as well.

Adding this extra material would also cut down on the amount of clay and sand that is used for building. According to the study:

“A second and seemingly unrelated environmental issue is the massive excavation of virgin soil for brick production. The annual production of 1500 billion bricks globally requires over 3.13 billion cubic metres of clay soil—equivalent to over 1000 soccer fields dug 440 m deep or to a depth greater than three times the height of the Sydney Harbour Bridge.”

In a 2018 book, The World in a Grain: The Story of Sand and How It Transformed Civilization, author Vince Beiser makes the case that the world is actually running out of the sand to keep up with the current demand for products from concrete to computer chips.

The massive dredging projects to harvest sand and clay also has an incredibly detrimental impact on the environment as some of the best clay for building is taken from beneath waterways, causing significant damage to the local wildlife and ecosystem.

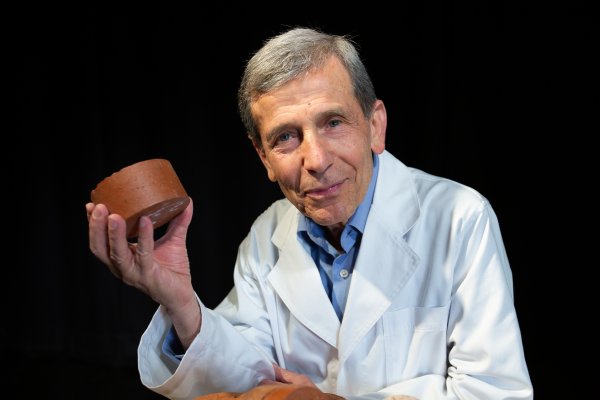

Professor Abbas Mohajerani, a civil engineer in RMIT’s School of Engineering and one of the lead researchers in the study, pointed out that this new process could help alleviate two separate environmental issues at the same time, both the overabundance of biosolid waste and the unsustainable soil evacuation required for traditional building materials.

“More than 3 billion cubic metres of clay soil is dug up each year for the global brickmaking industry, to produce about 1.5 trillion bricks. Using biosolids in bricks could be the solution to these big environmental challenges. It’s a practical and sustainable proposal for recycling the biosolids currently stockpiled or going to landfill around the globe,” Mohajerani says.

Hemp has also been proven as a sustainable building material, as Truth Theory has reported in the past. As we reported In 2019, Dun Agro, a progressive-thinking, housing company from the Netherlands has created an assembled pre-fab house made from hempcrete.

IMAGES CREDIT: RMIT University

Source: RMIT University

Leave Comment: